In different sectors, from power generation to oil and gas, to chemical processing and pharmaceuticals, tubes play a significant role in transporting fluids, gases, and so on. On the one hand, seamless operation is essential for efficient production, product quality, safety, etc. On the other hand, fouling and the accumulation of unwanted deposits can have a significant impact on performance.

This is where an automatictube cleaning system in Singapore comes in. It acts as an innovative solution that has pretty much revolutionised how maintenance practices are performed in various industries.

Simply put, there is so much to the said solution that is why it has become some sort of a fad nowadays. Read on and find out what it is all about.

Automatic tube cleaning system: A quick look

In general, an automatic tube cleaning system or ATCS is made up of cutting-edge devices that are specifically designed to ensure that the cleanliness of heat exchanger tubes is not compromised in any way. They operate by removing deposits from the inner surfaces of the said tubes. By doing so, they ensure optimal heat transfer in arguably the most effective and efficient way possible.

Automatic tube cleaning system: How it works

In general, the operation of an automatic cleaning system involves a couple of key components:

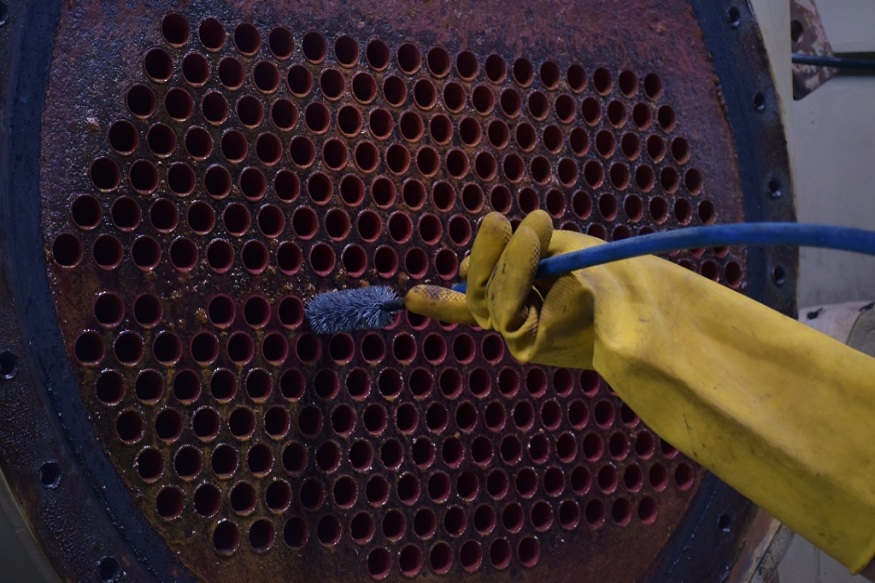

- Cleaning mechanism

The said system usually employs different cleaning mechanisms that include brushes, a ball cleaning system, or projectiles that are propelled through the tubes with the use of air or water supply. The whole cleaning process is automated as well as integrated seamlessly into the operation of an extensive heat exchange system, all with minimal human intervention.

- Control system

A smart control system is utilised in the operation of an ATCS. In the process, monitoring parameters are used: pressure, flow rate, temperature, etc. The operation of the said control system is based on real-time conditions or predefined criteria and initiates the cleaning cycle as necessary. This, in an effort to maintain optimum heat transfer efficiency.

- Cleaning frequency

With regard to the frequency of cleaning cycles, they can be pre-set based on operational requirements or dynamically adjusted based on real-time data. Some systems also utilise sensors to monitor the degree of fouling within heat exchanger tubes. This is necessary to trigger cleaning cycles in certain instances; by doing so, energy efficiency can be optimised, and water consumption can be minimised.

- Integration with current systems

A vast majority of automatic tube cleaning systems on the market, including those that come with an auto tube cleaning system and condenser tube cleaning system can be easily integrated into existing heat exchange systems minus significant modifications. This feature ensures compatibility and, at the same time, cuts down installation costs as well as downtime during the implementation phase.

Automatic tube cleaning systems: The benefits

- Improved efficiency

By ensuring that heat exchanger tubes are well-maintained, an ATCS ensures optimal heat transfer efficiency. In the process, it reduces energy consumption as well as operating costs. Studies suggest that ATCS can deliver significant savings based on the application as well as operational conditions, among other things.

- Extended equipment lifespan

Constant removal of deposits can prevent corrosion and fouling within heat exchanger tubes. As straightforward as it may seem, this can prolong the lifespan of important equipment. This can also reduce the frequency of maintenance as well as downtime. This may benefit companies in the long run by improving the reliability of critical assets.

- Improved reliability

ATCS can minimise the risk of equipment failures as well as unplanned downtime that is often associated with fouling-related issues. By automating the cleaning process, the said system can ensure consistent performance as well as operational reliability. This, in turn, can enhance process efficiency as well as overall productivity.

- Cost savings

While the initial costs with regard to ATCS purchase and installation may seem significant, it is safe to say that the benefits of the said system can more than offset the said expenditure. Plus, the long-term cost savings can outweigh the huge upfront expense. Furthermore, reduced energy consumption, reduced maintenance, extended equipment lifespan, and so forth, can result in significant cost savings if the overall operational life of the said system is factored in.

- Safety and compliance

ATCS, given that it is properly installed and manufactured by a reputable company, can boost safety by cutting down the need for manual cleaning activities, which often result in exposure to chemicals, confined space entry, and others. In addition, it can ensure compliance with both local and international industry standards as well as regulations.

- Environmental sustainability

The enhanced energy efficiency feature that is brought by an ATCS can contribute to a significant reduction of carbon footprint and its environmental impact. That said, by optimising energy consumption and cutting down chemical usage for conventional manual cleaning, the said system can promote sustainability and, in the process, comply with environmental regulations.

Summing up

In the end, the adaptation of an automatictube cleaning system in Singapore can deliver tangible benefits such as energy savings, cost reductions, operational reliability, and environmental sustainability, among others. Consequently, as industries strive to optimise their procedures and minimise downtime, automatic tube cleaning systems are heralded as indispensable tools that can complement the pursuit of efficiency and excellence of countless companies.